In modern manufacturing, automation plays an important role in improving productivity and optimizing processes. Vibrating hoppers (vibrating bowls) are indispensable equipment, helping to automatically feed small parts. In particular, vibrating hoppers with spiral bowl designs bring outstanding efficiency. This design helps to optimize space, increase storage capacity and ensure continuous feeding, improving production productivity.

So what is a spiral bowl vibrating funnel? What is its structure and operating principle? What are the advantages of a spiral bowl over a traditional round bowl? And in which industries is a spiral bowl vibrating funnel applied? This article will answer all your questions about a spiral bowl vibrating funnel. Let's SWOER Find out more!

What is a spiral bowl vibrating funnel?

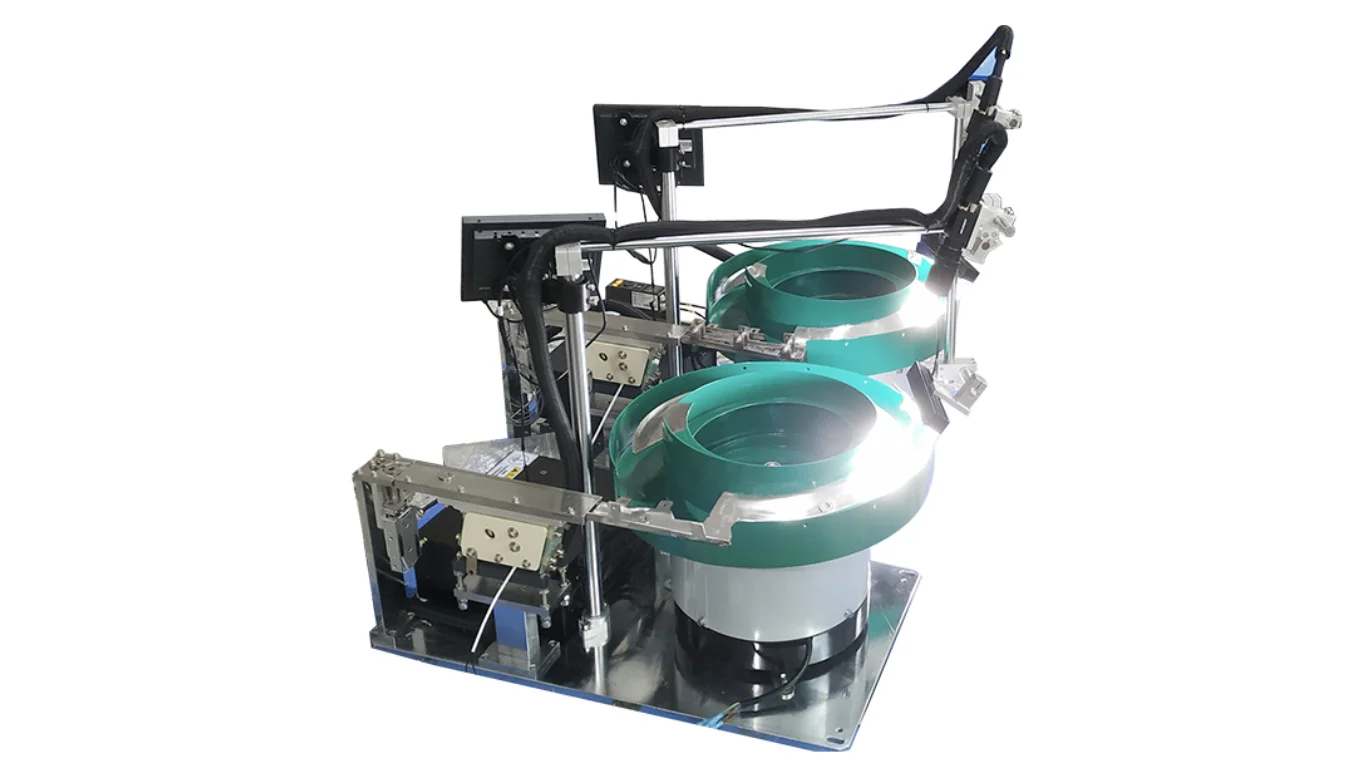

The spiral bowl vibrating hopper basically has the same function as the round bowl vibrating hopper, that is, automatically classifying, orienting and feeding small parts. The difference lies in the design. spiral vibrating bowl, helps optimize space and improve feeding efficiency.

Comparison with round bowl vibrating funnel:

Characteristic | Round bowl vibrating funnel | Spiral bowl vibrating funnel |

Shape of vibrating bowl | Round | Spiral |

| Size | More cumbersome | More compact |

Capacity | Limit | Bigger |

| Feed efficiency | Lower | Higher |

Expense | Lower | Higher |

| Application | Suitable for large size and weight parts | Suitable for round, lightweight details |

Structure and operating principle

To better understand how the spiral bowl vibrating funnel works, let's "dissect" the structure and explore the operating principle of this device:

Detailed structure

The vibrating hopper with spiral bowl consists of the following main parts:

- Spiral bowl: Spiral shape, made of stainless steel. Bowl size depends on the type of part and required capacity. Inside there is a spiral path and trap.

- Track: Detailed guidance from the bottom to the mouth of the bowl in a spiral structure.

- Escape: Eliminate parts that are misaligned or do not meet standard dimensions.

- Vibrator: Consists of electric motor and eccentric block, creating vibration to help move the part.

- Control system: Adjust vibration speed, feed time and other parameters.

Working principle:

The vibrating hopper with spiral bowl works on the principle vibrate and centripetal force.

- Vibrate: The electric motor rotates the eccentric block, creating vibration for the vibrating bowl.

- Move: This vibration combined with the spiral design of the bowl will create a centripetal force, causing the parts to move upward in a spiral path.

- Classify: The traps will remove the unsatisfactory parts, ensuring that only the correctly oriented parts reach the bowl mouth.

- Orientation: Spiral paths and traps also contribute to detail orientation.

- Feeding: Qualified parts will be removed from the bowl mouth and fed into the production line.

Advantages of vibrating funnel with spiral bowl

The vibrating hopper with spiral bowl not only "scores" with its unique design but also "conquers" users with its outstanding advantages, bringing optimal efficiency to the production process.

- Space saving: Spiral design helps optimize space, suitable for limited production spaces, helping businesses save installation space.

- Improve efficiency: Spiral bowl has larger capacity compared to traditional round bowls, especially with small, lightweight pieces. The spiral design helps Increase feeding speed and efficiency, ensure continuous flow of detail.

- Flexible: Vibrating funnel with spiral bowl suitable for many kinds of details and application ranging from electronic components to plastic granules, pellets, etc. Parameters such as vibration speed and tilt angle can be adjusted to suit feeding requirements.

- High durability: Made from high quality materials (usually stainless steel), guaranteed durability and abrasion resistance. Activities stable, less damage, lengthen life span device.

In which industries are spiral bowl vibrating funnels "dominating"?

Spiral bowl vibrating hopper, with its outstanding advantages of space saving, efficiency improvement and flexibility, is being widely used in many industries. Here are some typical examples:

Electronic components manufacturing:

Supplying small and complex electronic components such as chips, capacitors, resistors, diodes, etc. for production lines of electronic circuit boards, mobile phones, computers, etc.

Pharmaceutical industry:

Supplying tablets, capsules, bottles, caps, labels, etc. to packaging, labeling, and inspection lines.

Food industry:

Feeding nuts, candies, cookies, etc. to the automatic packaging line.

Assembly industry:

Feeding small parts to assembly lines for products such as toys, medical equipment, household appliances, etc.

Choose a vibrating funnel with a spiral bowl

Spiral bowl vibrating hoppers are an efficient feeding solution, but to choose the most suitable equipment for your production needs, you need to carefully consider the following factors:

1. Detail type:

- Size and shape: Spiral bowls are suitable for small, lightweight parts. Determine the size and shape of the part to choose the appropriate size funnel.

- Material: Consider the material of the part (metal, plastic, etc.) to choose the material for making the vibrating funnel (stainless steel, plastic) and design the surface of the guideway (smooth, rough, anti-static, etc.).

2. Size:

- Hopper size: Choose the hopper size that fits the installation space and the number of parts to be stored.

- Path size: The path must be wide enough for the part to move freely without getting stuck.

3. Required productivity:

- Feed rate: Determine the feed rate required to meet production needs.

- Detailed weight: Estimate the volume of material required to be fed in a given period of time.

4. Working environment:

- Temperature, humidity, dust: Choose a vibrating hopper that can withstand the working environment conditions.

- Hygiene requirements: In some industries such as food and pharmaceuticals, it is necessary to choose a vibrating hopper with an easy-to-clean design that meets hygiene and safety standards.

5. Budget:

- Investment costs: Determine the budget for purchasing a vibrating funnel.

- Operating costs: Consider the cost of electricity consumption and maintenance.

Advice:

- Choose a reputable supplier: Choose an experienced, reputable supplier that provides quality products and good after-sales service (like SWOER).

- Request consultation, custom design: Each production line has its own requirements. Ask your supplier to advise and design a vibrating hopper to suit your specific needs.

Conclude

The vibrating hopper with spiral bowl is an efficient automatic feeding solution, especially suitable for demanding applications. space saving, high productivity and ability to handle small details flexibly. With Compact design, large capacity and high durability, spiral bowl vibrating hopper is widely used in many industries such as electronic components manufacturing, pharmaceuticals, food and assembly.

If you are looking for an automatic feeding solution Optimize for business, please learn more about the spiral bowl vibrating hopper and consider whether it is suitable for your production needs. SWOER Proud to be the supplier of vibrating funnel with spiral bowl high quality, diversity model, response all requests of the customer.

Contact us

Please let us know your material size and required speed.