SWOER specializes in providing customized industrial component feeders with flexible, high-quality solutions. With over 10 years of experience, we design efficient feeding systems that meet the needs of many industries such as automotive, electronics, and pharmaceuticals.

BEST SELLING

SWOER FEEDING MACHINES

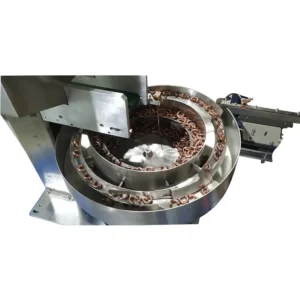

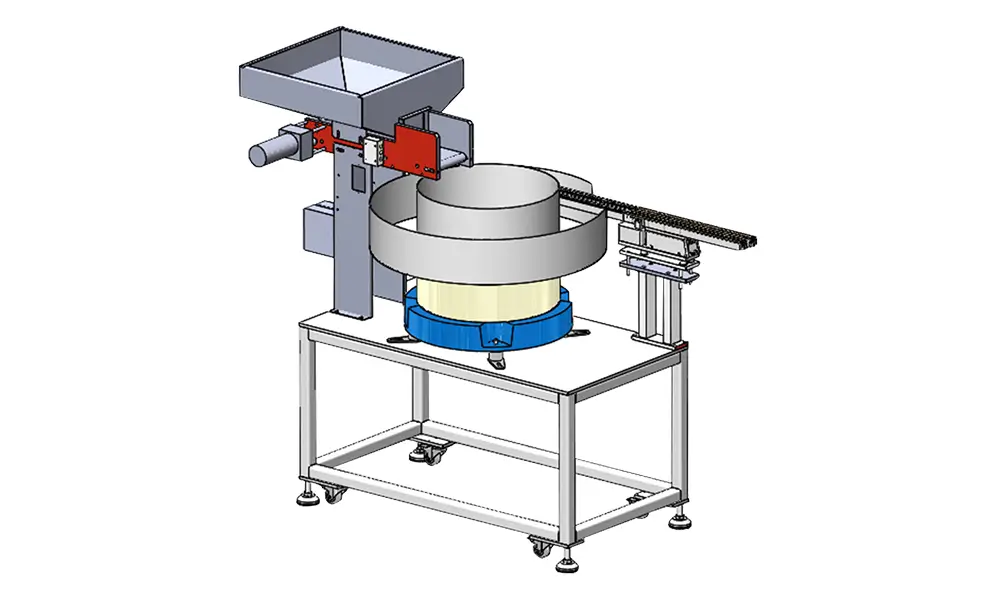

Vibrating feeder

Vibrating feeder helps to orient and feed materials accurately and continuously, increasing production efficiency for the automation industry.

Contact number: 0347 103 200

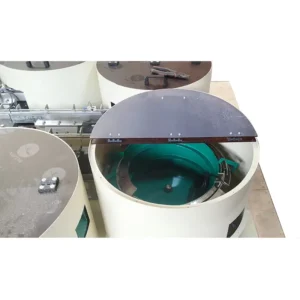

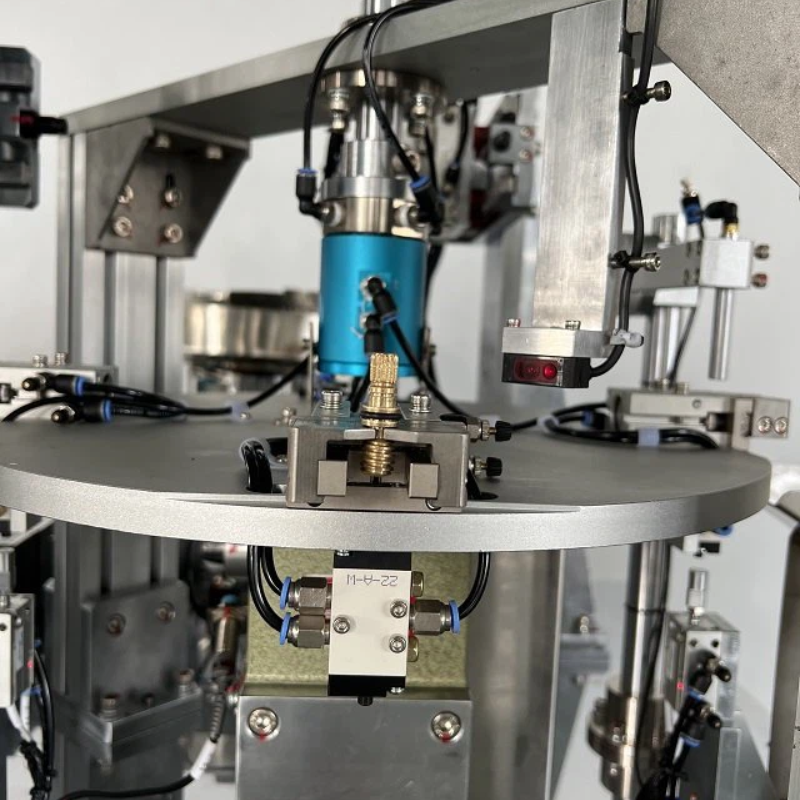

Centrifugal feeding system

Centrifugal feeding systems use centrifugal force to distribute materials quickly and accurately, optimizing automated production processes.

Contact number: 0347 103 200

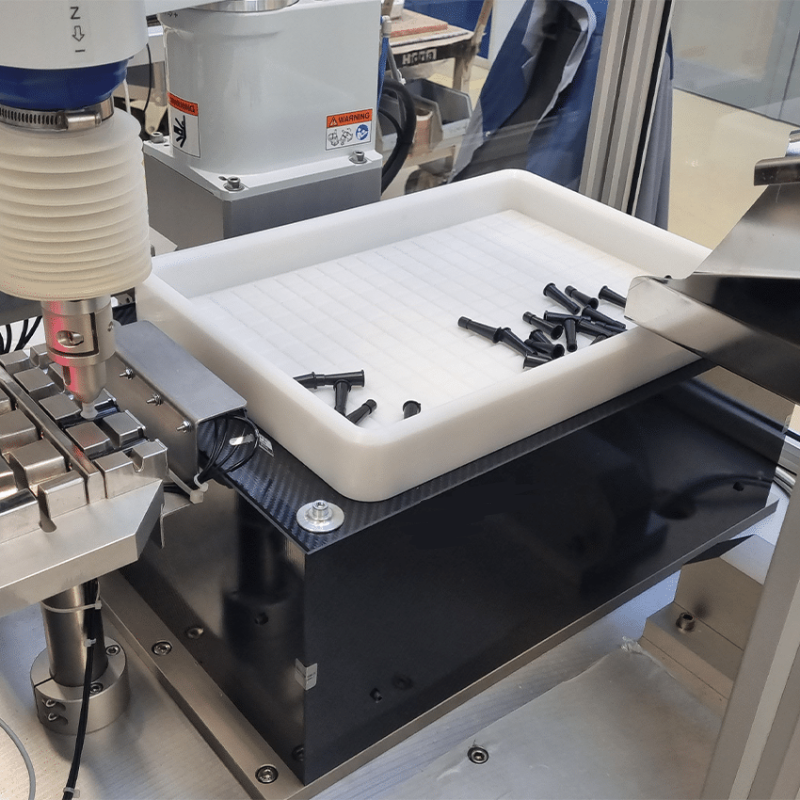

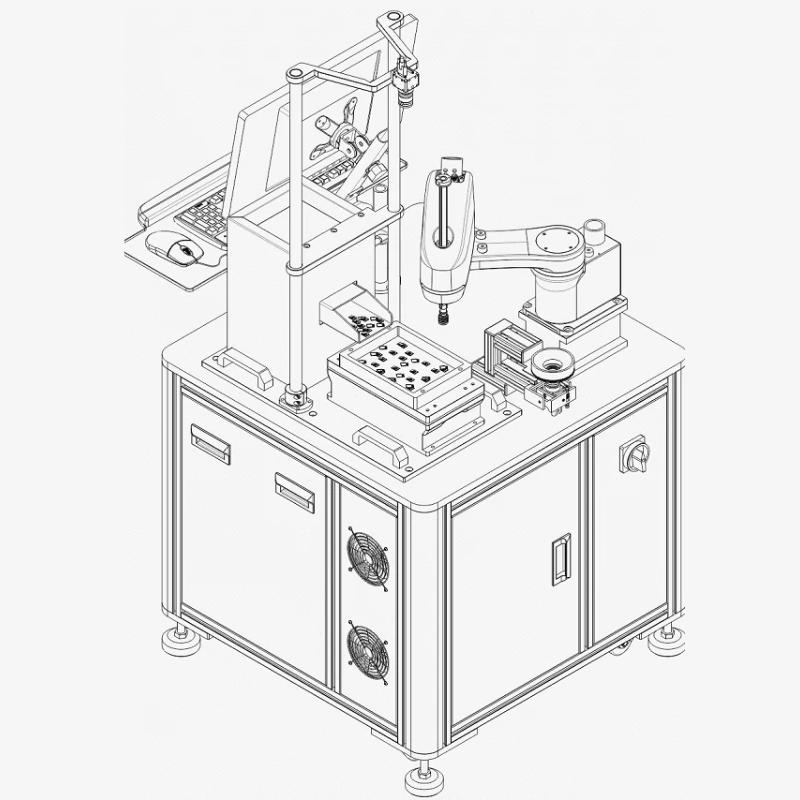

Flexible robot feeder

Flexible robot feeders optimize production processes by providing precise and flexible material feeding to robots.

Contact number: 0347 103 200BENEFITS OF OWNING SWOER FEEDING MACHINE

Automated systems help transport and sort small parts, increasing productivity and accuracy.

- Benefits in production: Save time, reduce labor costs, and automate processes, ensuring high performance.

- Production process: Starting from design, quality control, and customization according to customer requirements.

- Manufacturing materials: Choose materials that are durable, abrasion resistant and suitable for the production environment.

- Installation and testing: The system is installed and tested at the customer's factory to ensure stable operation.

SWOER FEEDING MACHINE DESIGN

SWOER automatic vibrating feeder is sophisticatedly designed, suitable for modern production processes. The product helps increase efficiency, reduce errors and ensure high durability during operation.

- Precision design: Ensures stability and efficiency in all working conditions.

- High quality material: Made from durable, abrasion resistant materials, well suited to harsh industrial environments.

- Easy to customize: Provide size and color options according to customer requirements.

- High performance: Optimize the feeding process, minimize machine downtime and increase production capacity.

CAPABILITY OF SWOER FEEDER

Industrial parts feeders help optimize production processes, increase efficiency and reduce errors. With smart design, this product brings many benefits to businesses in different industries.

- Increase productivity: Automate the feeding process, reduce machine downtime and increase production efficiency.

- Minimize errors: Minimize errors in feeding, ensure components are fed accurately.

- Cost savings: Minimize labor costs and optimize production processes.

- Flexible and customizable: Easily adjustable to production requirements and different component sizes.

APPLICATION OF FEEDING MACHINE IN PRODUCTION

Industrial feeders help automate production, increase efficiency, and reduce errors on assembly lines. Vibrating feeders, centrifugal feeders, and flexible feeders are widely used in many industries. Here are four key areas where these devices make significant contributions:

Automobile manufacturing industry

Vibrating feeders and flexible feeders are used in the feeding and positioning of small parts, ensuring the accurate and efficient assembly of automobiles.

Electronics and components industry

Feeders are used to feed small components such as chips, capacitors, and microcircuits during circuit board assembly.

Medical and pharmaceutical industry

These feeders help transport small medical parts such as needles, vials, and other components safely and accurately during the manufacturing process.

Food processing industry

Flexible feeders enable fast feeding of small parts, packaging of raw materials and finished products, while meeting strict hygiene and safety requirements.

WHY CHOOSE SWOER?

Years of experience

With over 10 years of experience in the vibrating feeding system manufacturing industry, SWOER is committed to providing optimal and efficient solutions to customers.

Superior quality

SWOER products are made from high-quality materials, ensuring durability and stable performance in harsh production environments.

Custom solutions

SWOER provides custom-designed vibrating feeding systems to precisely meet production and operating needs.

Customer service

SWOER always supports customers from consulting, design to installation and maintenance, ensuring satisfaction and efficiency throughout the usage process.

OUR PARTNERS

Frequently Asked Questions (Q&A)

Who is the leading supplier of flexible feeding and robot integration in Vietnam?

In Vietnam, SWOER is one of the leading reputable suppliers of integrated robots, flexible feeders, centrifuges, and vibrators. We provide comprehensive solutions for automation industries.

In which industries is SWOER flexible feeder applied?

SWOER flexible feeder is widely used in industries such as electronics, pharmaceuticals, food, mechanics, etc. to increase efficiency and accuracy in the production process.

What are the outstanding advantages of SWOER centrifuge?

SWOER centrifuges stand out with their durable design, high performance, and stable operation. The product is suitable for applications requiring high precision such as in the pharmaceutical and chemical industries...

Can SWOER vibrators be customized according to production needs?

Yes, SWOER vibrators are flexibly designed and can be customized according to the specific requirements of each production line, ensuring optimized work efficiency.

Does SWOER support equipment maintenance and repair?

SWOER provides professional maintenance, servicing, and repair services for all products, including flexible feeders, centrifuges, and vibrators, ensuring the equipment always operates stably.

How to contact SWOER for quotation and consultation?

You can contact SWOER via the official website, hotline, or email to receive detailed quotes and advice on the most suitable robot and industrial equipment integration solutions.