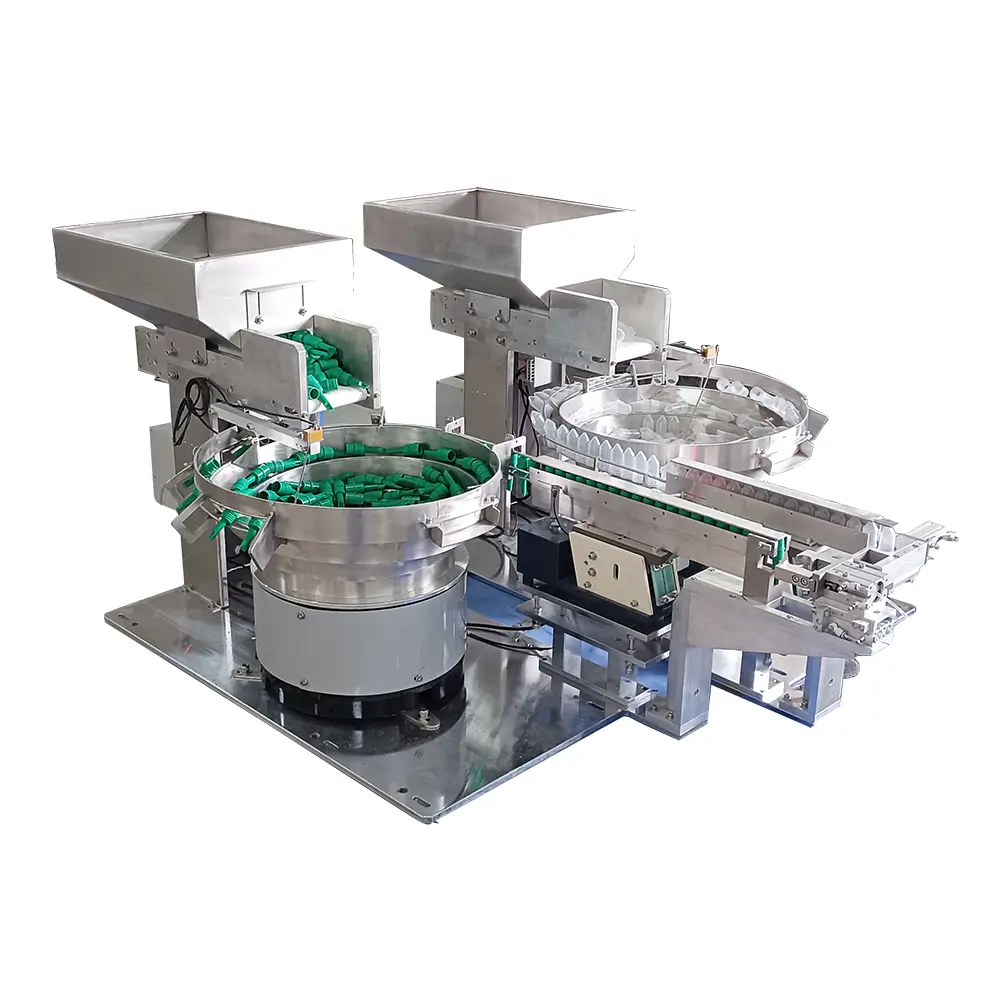

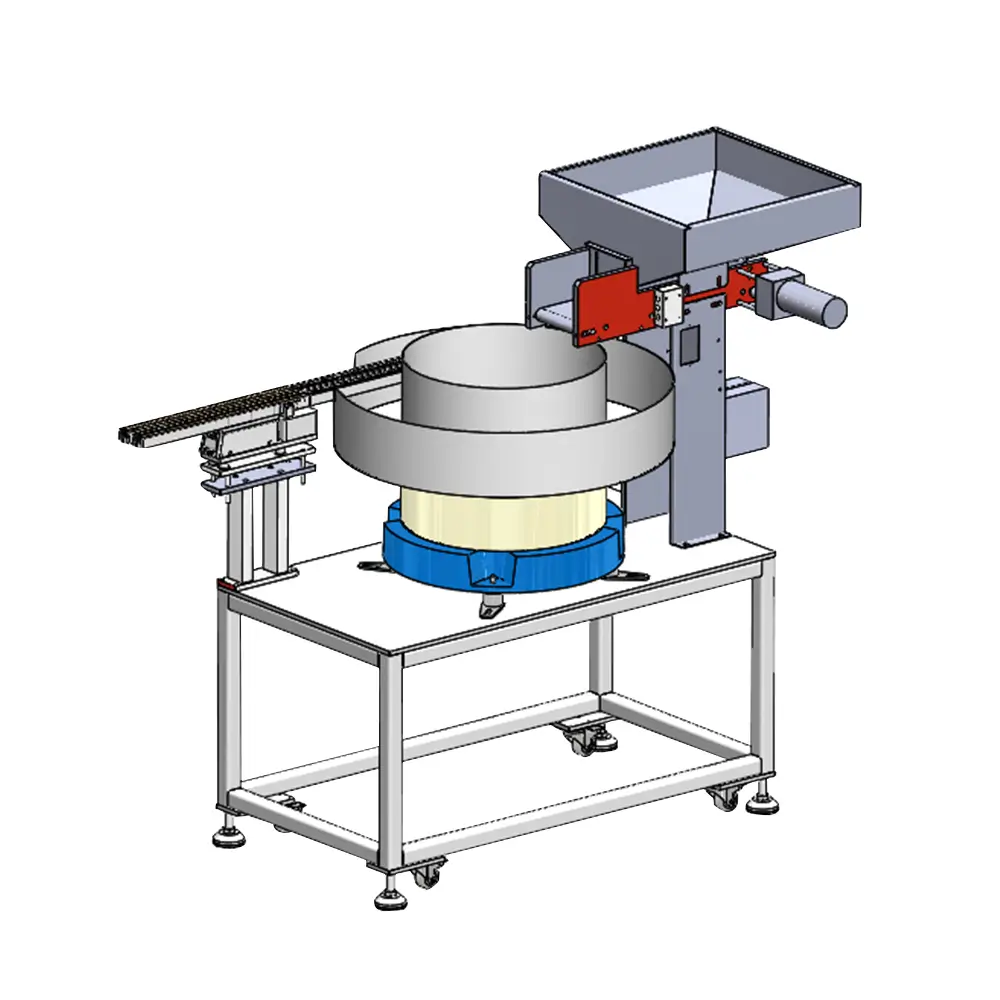

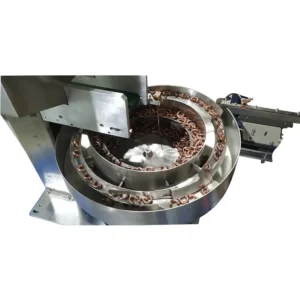

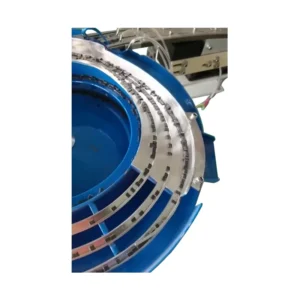

In the field of manufacturing automation, vibrating hopper feeder plays an important role in orienting and supplying components accurately, helping to optimize the production process. SWOER is proud to be a leading supplier of vibrating feeder, specially designed for a wide range of materials and applications, ensuring high precision, stable operation and superior performance.

SWOER offers a wide range of products. vibrating hopper feeder high quality, meeting the automation needs of many industries. With optimized design, high precision and flexible customization, SWOER's workpiece feeding systems help improve production efficiency, reduce errors and enhance stability. We provide circular vibrating funnel, linear vibrating funnel, step vibrating funnel Suitable for all types of components from electronics, pharmaceuticals, food to precision mechanics. The system is made from durable materials, integrated with modern control technology, helping to optimize the speed of feeding and reduce operating costs.