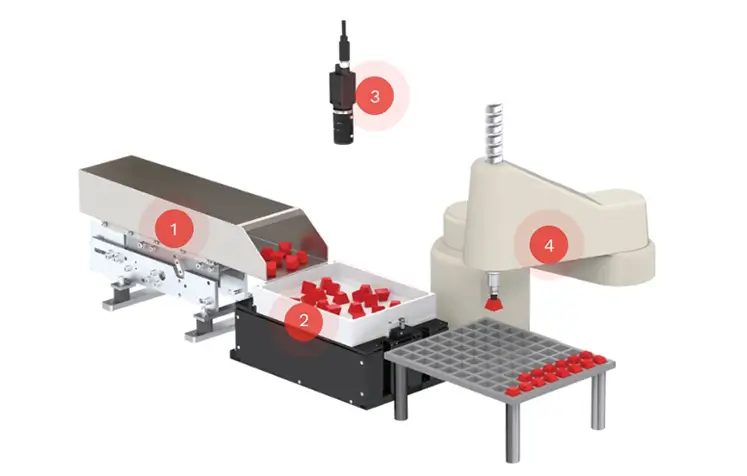

APPLICATION OF SWOER FEEDING MACHINE IN MANUFACTURING INDUSTRIES

SWOER's feeder is an advanced solution that automates the process of supplying components and products in production lines. Thanks to its ability orientation, classify and accurate feeding, SWOER feeders are widely used in many industries, helping increase productivity, Reduce errors and optimize production processes.

Applications in manufacturing industries

1. Electronics industry

In the electronic components manufacturing industry, SWOER feeders help Provide and accurately orient small components like:

- Microchips, capacitors, resistors, semiconductor chips

- Connectors, connectors, SMD components

- Sensors, micro switches

Using a feeder helps Reduce assembly errors, improve performance and accuracy, especially in high-speed automated production lines.

2. Mechanical engineering and manufacturing

SWOER Feeder Support automatic feeder for mechanical processing systems, especially small parts such as:

- Bolts, nuts, screws

- Screw, gear, bearing

- Small metal components in the automotive and aerospace industries

With the ability stable and accurate feeding, SWOER helps improve product quality, reduce waste and optimize production.

3. Automotive Industry

The automotive industry has high requirements for assembly accuracy, especially for small components. SWOER feeders are applied to Feeding automated assembly robots, ensure:

- Precise positioning of parts such as screws, pins, bearings

- Support automated assembly process

- Minimize downtime and improve line productivity

4. Pharmaceutical industry

In the pharmaceutical industry, SWOER feeders help automate drug packaging and sorting processes, applies to:

- Pills, capsules

- Syringes, capsules, vials

- Pharmaceutical packaging

Guaranteed feeder high precision and hygiene, helping the pharmaceutical industry meet stringent manufacturing standards.

5. Food industry

In the food processing industry, SWOER feeders help Provide accurate raw materials and quantities, applies to:

- Dietary supplement tablets

- Packing seeds, spices, candy

- Feeding for automatic packaging machine

With material design food safe, anti-corrosion, SWOER feeder ensures clean, safe and effective in food production.

6. Automatic packaging industry

SWOER's feeders are integrated into automatic packaging systems, helping precise positioning and feeding parts such as:

- Bottle cap, can cap

- Box, plastic packaging

- Packaging accessories

This application helps tIncrease packaging speed, reduce errors and optimize production costs.

Benefits of using SWOER feeder

- Increase productivity: Helps the production line operate continuously without interruption, thereby improving the overall efficiency of the production system.

- High precision: Precise component orientation, minimizing assembly errors, ensuring consistent product quality.

- Reduce manual labor: Save labor costs, reduce the risk of human error, and improve working conditions for employees.

- Optimize production process: Easily integrates into modern automation systems, helping businesses achieve higher performance with less disruption.

- Save production costs: Reduce material loss, optimize labor and energy consumption, thereby increasing profits and optimizing operating costs.

- Flexible and customizable: SWOER feeders can be designed according to the specific needs of each business, ensuring that they meet the specific requirements of each industry.