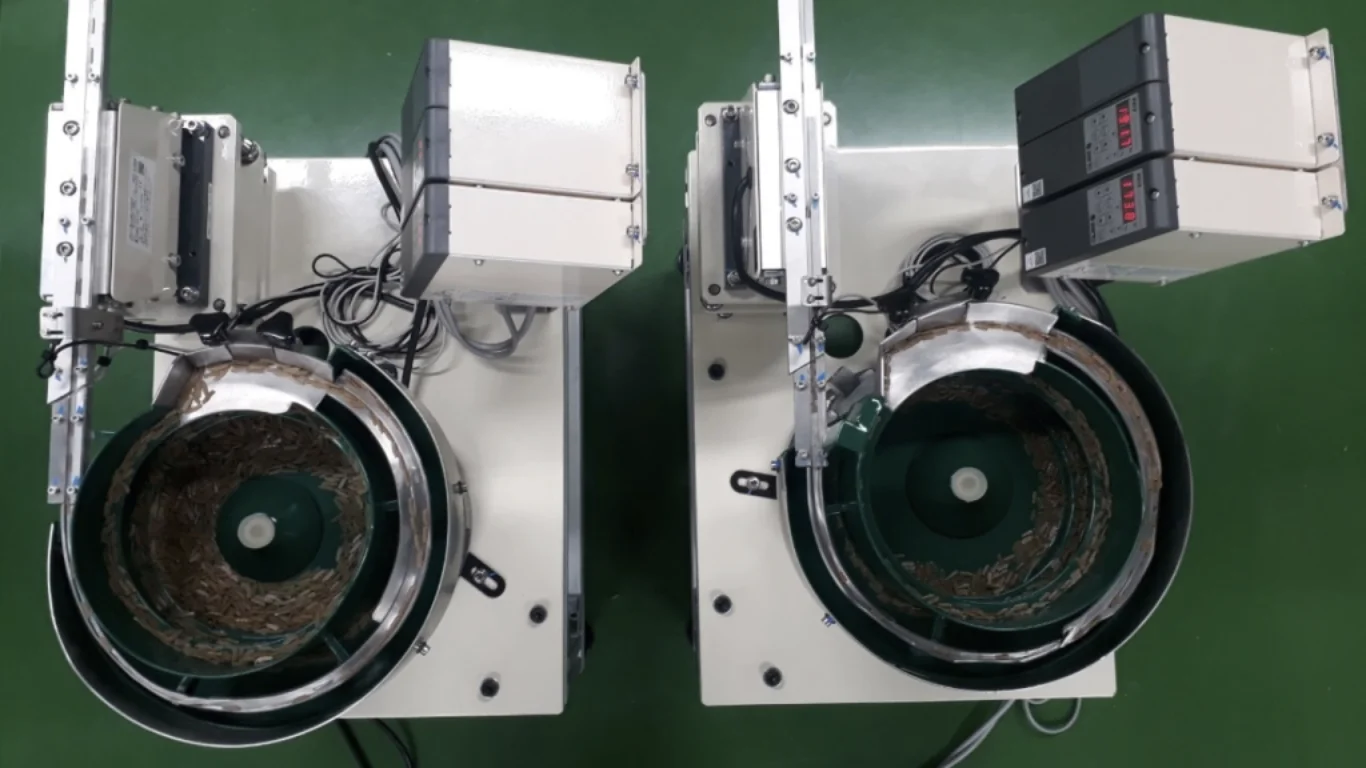

Vibrating feeders are important equipment in automated production lines, helping to orient and feed small parts accurately and efficiently. However, like any other equipment, vibrating feeders need to be cleaned regularly to ensure smooth operation and long life.

Cleaning the vibrating hopper not only helps improve work efficiency, but also contributes to improving product quality, minimizing downtime and saving maintenance costs. This article SWOER will guide you on how to clean the vibrating feeder hopper effectively and safely, helping the device operate stably and durably.

Benefits of cleaning vibrating funnel

Regular cleaning of the vibrating feeder not only helps to clean the equipment but also brings many practical benefits. This helps businesses save costs and improve production efficiency.

Improve performance

Dust, debris, and grease on the vibrating funnel can cause friction. This hinders the movement of the workpiece, reducing operating efficiency. Regular cleaning helps remove these agents. This helps the vibrating funnel operate smoothly and maintain stable productivity.

Prolong life

Dust and impurities can wear out parts of the vibrating funnel such as spirals, traps, vibrating motors, etc. Regular cleaning helps reduce wear and tear and limit damage. As a result, the life of the equipment is extended, saving businesses money on repair and replacement costs.

Improve product quality

A clean vibrating hopper helps prevent contamination of the workpiece. This is especially important in industries that require high levels of cleanliness such as food, pharmaceuticals and electronics. Regular cleaning of the equipment helps ensure hygiene and quality of the output product.

Minimize downtime

Accumulated dirt can cause problems, forcing equipment to stop for repairs. Cleaning the vibrating hopper helps prevent breakdowns, reducing production downtime. This keeps the line running smoothly, ensuring production progress.

When should the vibrating feeder be cleaned?

Determining when to clean the vibrating feeder depends on many factors, including frequency of use, work environment, and type of feed. Some general guidelines include:

Regular cleaning

- Daily: If the vibrating funnel operates continuously at high intensity, in a dusty environment, it should be cleaned daily.

- Weekly: For vibrating funnels operating at medium intensity, in relatively clean environments, weekly cleaning is possible.

- Monthly: If the vibrating funnel is used sparingly and in a clean environment, it can be cleaned monthly.

Note: It is recommended to establish a regular cleaning schedule and record it for monitoring. The cleaning frequency can be flexibly adjusted based on the actual situation.

Clean up when problems are detected

- Unstable operation: If the vibrating hopper is not working properly, the workpiece is stuck, clogged or the feeding speed is uneven, it should be checked and cleaned immediately.

- Strange noise: If the vibrating funnel makes strange noises, it may be caused by dirt or debris, and needs to be cleaned to fix the problem.

- Signs of contamination: If the vibrating funnel is found to be contaminated (grease, debris, dirt, etc.), it must be cleaned immediately to avoid affecting product quality.

Cleaning when changing blank type

- Avoid cross contamination: When switching to feed another type of blank, it is necessary to thoroughly clean the vibrating hopper to avoid cross-contamination between blanks, ensuring product quality.

- Especially important: This is especially important in the food and pharmaceutical industries where strict hygiene requirements are required.

Instructions for cleaning vibrating funnel properly

Proper cleaning of the vibrating funnel not only helps the device operate effectively but also prolongs its life and ensures user safety. Detailed instructions here:

Prepare

- Disconnect power: Ensure absolute safety before cleaning.

- Prepare cleaning tools:

- Soft bristle brush

- Soft, clean towel

- Special cleaning solution (non-corrosive)

- Compressed air (if any)

- Protective gloves

Cleaning steps:

1. Disassemble the parts

Disassemble the hopper, spiral, trap, etc. (if possible). This allows for a more thorough cleaning of each part.

2. Remove dirt and clean

- Use a soft cloth to wipe away grease and dirt from the feed tray.

- Clean with neutral detergent, ammonia solution or specialized detergent.

- Dirty surfaces can be cleaned with soap, warm water or a mild detergent.

- Labels and cling film should be washed with warm water, mild detergent or rubbed clean with alcohol.

- Rust stains can be removed with 10% nitric acid, abrasive cleaner or special detergent.

- If the surface has rainbow marks, wash with warm water to remove any detergent or oil residue.

- If acid comes in contact, wash immediately with water. Then dip in neutral ammonia or soda solution and rinse with warm water.

3. Dry

Use a clean cloth to dry the parts. Make sure there is no cleaning solution left on the surface.

4. Reassemble

Reassemble the parts according to the correct procedure. Make sure the parts are installed correctly.

5. Check the operation

After assembly, test the vibrating hopper to ensure the equipment operates normally.

Note:

- Refer to the manufacturer's cleaning instructions for detailed and safe steps.

- Do not use sharp objects to avoid scratching the surface of the vibrating funnel.

- Choose a cleaning solution suitable for the material used to make the vibrating funnel (stainless steel, plastic, etc.) to avoid corrosion and damage.

Conclude

Cleaning the vibrating feeder is a simple task but brings great efficiency, helping the equipment operate stably, prolonging its life and ensuring product quality. By performing regular and proper cleaning according to the detailed instructions in the article, you can optimize the performance of the vibrating feeder, save maintenance costs and improve the competitiveness of the business. Remember, equipment maintenance is an important factor in production. If you need more information or advice on vibrating feeder cleaning and maintenance solutions, do not hesitate to contact us. SWOER. We are always ready to support you!

Contact us

Please let us know your material size and required speed.