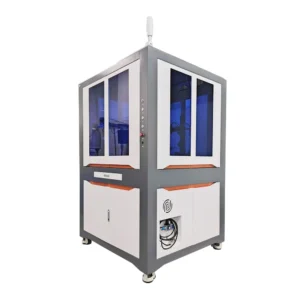

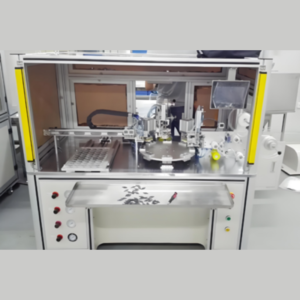

Product Introduction

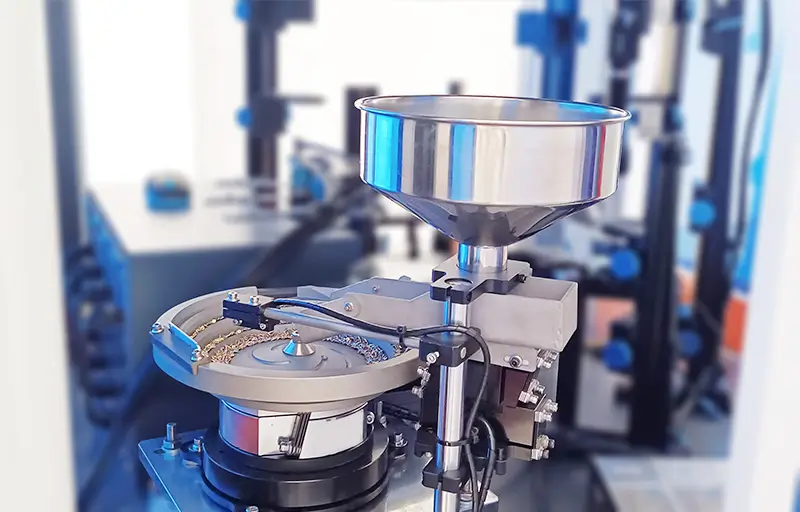

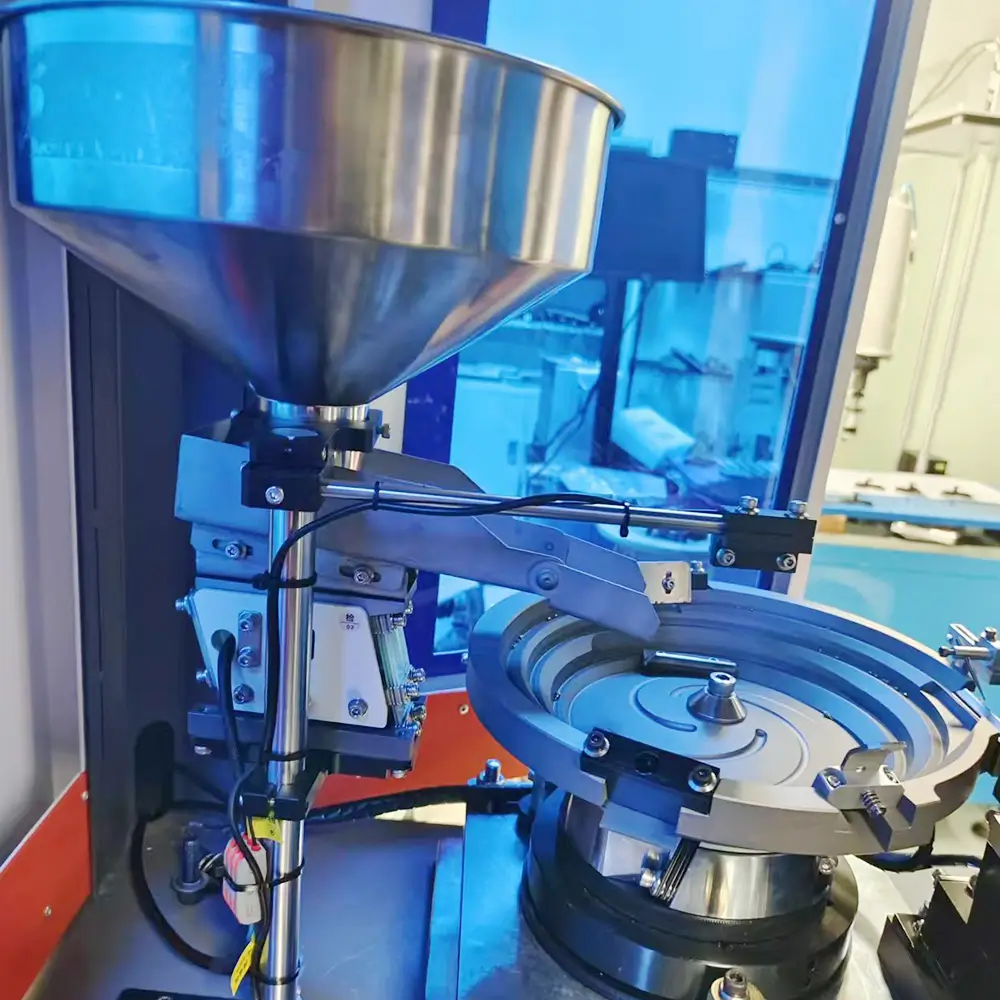

The turntable visual inspection machine is an automatic inspection equipment developed to target the size, appearance and other defects of various parts. After using a loading mechanism such as a vibrating plate to automatically transport the parts to the glass turntable, the visual inspection station will perform image. processing on the parts. The motion controller completes the constant speed rotation of the glass turntable, the encoder feedback of the material position and the hardware position comparison output to drive the multi-station CCD camera and the air blower to achieve fully automatic multi-dimensional shape, size and other aspects of inspection and screening. Application market The turntable visual screening machine is widely used in industrial manufacturing fields such as 3C electronics, lithium batteries, electronic components, semiconductors and hardware.

Advantages

- Test results are stable and very consistent

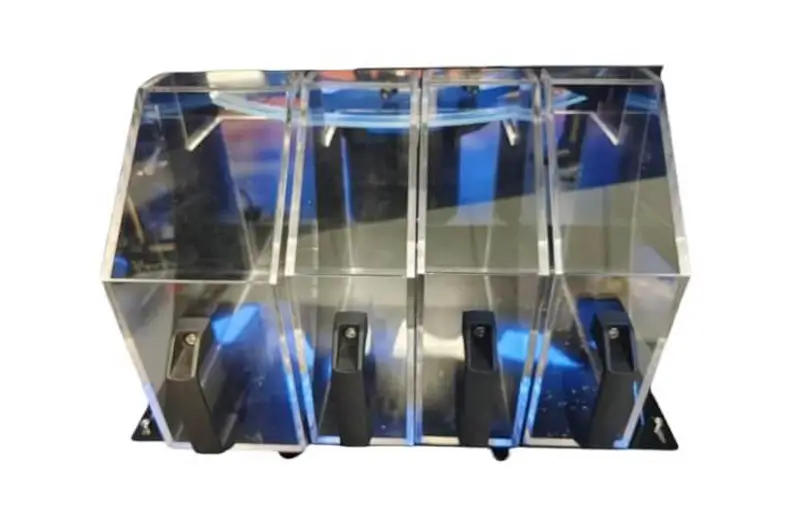

- Automatically screen and classify defective products, eliminate them and improve product quality

- Visual aerial photography reduces machine CT and improves efficiency compared to static photography

- One person operating one machine can replace 2-6 manual operations and increase production productivity.

- It is possible to monitor online whether each production inspection process is performed reliably and efficiently.

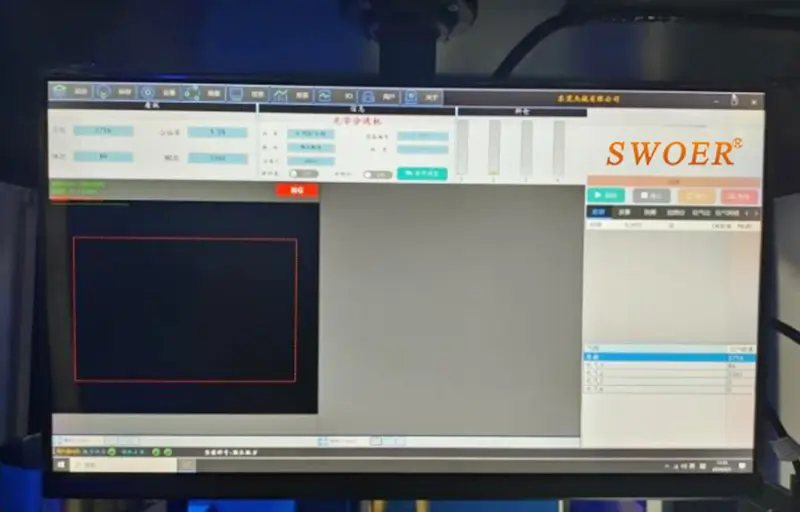

- o Compared with traditional PLC + touch screen solutions, it has higher integration, better cost efficiency and better response so it is faster and more efficient

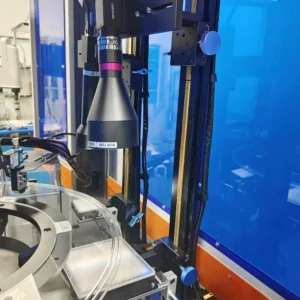

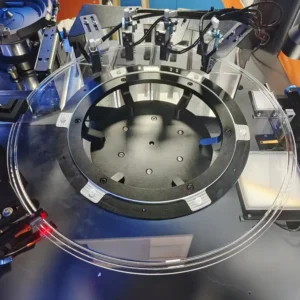

Show different components

Motion controller

Products to be tested

Sense and record material location

Activate the camera to take a photo

Visual system processing

Screening good and bad products

Reviews

There are no reviews yet.