Product Specifications

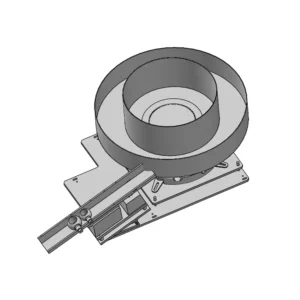

| Product Name | Vibrating feeding system for cylindrical cone caps |

| Material | AL7075 / SUS304 |

| Material properties | Cold-treated forged alloy, high strength, high hardness |

| Voltage | 220V |

| Capacity | 65W /150W /180w / 220W / 350W |

| Certification | CE,ROHS,ISO9001 |

| Guarantee | one year |

| Minimum Order Quantity | 1 set |

| Delivery date | 28 days |

| Payment method | T/T deposit 30%, balance paid before delivery |

| Country of origin | China |

Product information to know when ordering custom vibrating feeder:

1. Information about the blank / material:

- Material Type:

- Material (metal, plastic, ceramic, etc.)

- Properties (fragile, sticky, abrasive, etc.)

- Material size and shape:

- Detailed dimension drawing or specimen

- Complexity of shape

- Material weight:

- Weight of each material

- Required feed rate

- Material status:

- Loose or packaged form

- Condition of the material surface, is it smooth, is it greasy etc.

2. Requirements for blank supply:

- Feed speed:

- Quantity of material to be supplied per minute

- Speed requirements of the production line

- Feed direction and position:

- In which direction should the material go to the next stage?

- Location and height of the feed outlet

- Feeding accuracy:

- Requirements for material positioning accuracy

- Is there a specific arrangement required?

- Feed stability:

- Is continuous feeding required?

- Requirements for feed stability.

3. Device environment:

- Work space:

- Usable space dimensions for feeder installation

- Layout of the production line

- Working environment:

- Environmental conditions such as temperature, humidity, dust, etc.

- Are there any special requirements such as dustproof, explosion-proof, etc.?

- Power requirements:

- Power supply parameters such as voltage, frequency, etc.

- Noise requirements:

- Is there a noise limit?

4. Automation integration:

- Integrate with existing equipment:

- What devices need to be connected?

- Control signal requirements

- Control system requirements:

- Is PLC control required?

- Is sensor feedback required?

5. Other special requirements:

- Cleaning requirements:

- Is easy to clean design required?

- Food or medical requirements

- Maintenance requirements:

- Convenient maintenance.

- Are the parts easy to replace?

- Safety requirements:

- Is safety equipment required?

Reviews

There are no reviews yet.