In modern industries, screening, classification and separation of raw materials play an extremely important role. Vibrating screen is an indispensable device in the production process, helping to improve work efficiency, minimize material loss and improve product quality. So what are the specific benefits of vibrating screens? Let's SWOER Find out in the article below.

What is a vibrating screen?

Definition and working principle

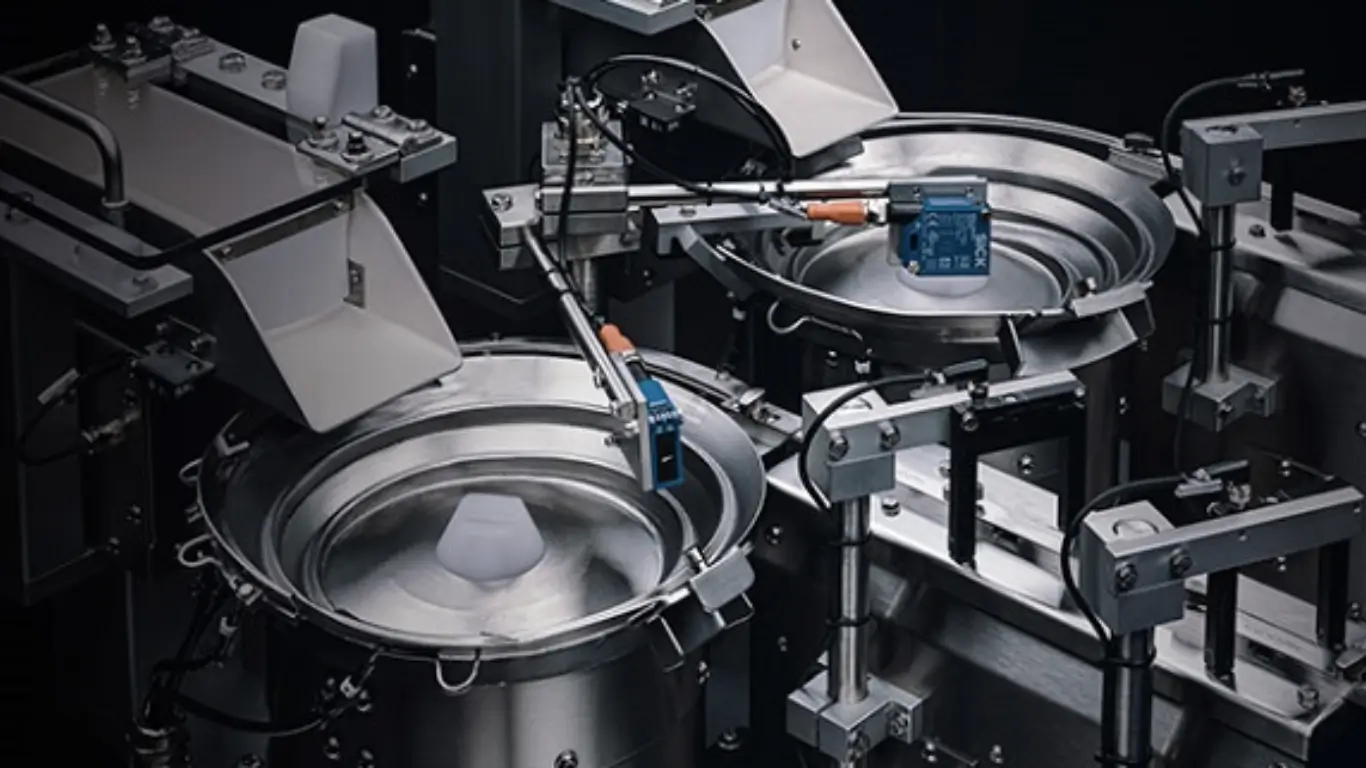

Vibrating screen is a raw material screening equipment that operates based on mechanical vibration. Thanks to the vibrating motion, the raw material is classified according to particle size or specific gravity, helping to optimize the cleaning and classification process of the raw material.

Common types of vibrating screens

- Linear vibrating screen: Suitable for mining, metallurgy, construction materials industries.

- Circular vibrating screen: Used in food, chemicals, pharmaceuticals.

- Ultrasonic vibrating screen: Specialized for superfine materials such as powder and special chemicals.

- Vibrating screen for water separation: Applications in wastewater treatment and mining.

Benefits of vibrating screen in production

Increase the efficiency of screening and classifying raw materials

- Work continuous, automatically helps optimize the production line.

- High precision, ensuring raw materials meet standard sizes, effectively removing impurities.

- Minimize waste of raw materials, improve processing efficiency.

- Adaptability to a wide range of raw materials, from coarse grains to ultra-fine powders.

Improve output quality

- Ensure uniform raw materials, helping products meet quality standards.

- Reduce production errors due to substandard raw materials.

- Reduce failure and recycling rates, optimize production processes.

- Improve accuracy in material classification, reduce error rate.

Save labor costs and optimize production costs

- Reduce dependence on manual labor, increase automation.

- Minimize material waste and optimize production costs.

- Reduce maintenance and repair costs thanks to durable, easy-to-clean design.

- Save energy thanks to optimal operating mechanism, reducing energy consumption.

Multi-industry applications

- Food industry: Screening flour, seeds, cereals, sugar, coffee...

- Pharmaceutical industry: Filtering medicinal powder, tablets, excipients...

- Chemistry: Classification of plastic granules, powder chemicals, color powders...

- Mining industry: Filter sand, rocks, minerals, precious metals...

- Construction industry: Screening cement, sand, gravel, gypsum...

- Recycling industry: Classification of plastic, rubber, scrap metal...

Conclude

Industrial vibrating screens provide High performance, cost savings, improved product quality and suitable for many manufacturing industries. If you are looking for effective screening solution, please contact us immediately SWOER for detailed advice!

Contact us

Please let us know your material size and required speed.